Assessing the Effects of Operating Regimes on Track

Written by Robert Tuzik, Editor-in-Chief and Publisher of Interface Journal

RT&S, JULY 2023 ISSUE – Operating practices on North American railroads have changed within recent years. Precision Scheduled Railroading (PSR) and its variants, which have been adopted by most of the Class 1 railroads, have led to changes in train lengths and speeds. In some cases, railroads are running shorter and faster trains; in most cases, they’re running longer, heavier, and slower trains.

“Each operating regime has difference requirements, but in either case, one of the fundamental aspects of PSR is to do more with less — fewer cars, locomotives, yards, crews, staff, and less track, where it’s not needed,” Gary Wolf, President of Wolf Railway Consulting, told participants at the WRI 2022 Wheel/Rail Interaction conference. More specifically, he said, PSR and its variants focus on:

- Fewer touches per car – less switching, more destination blocking

- Car performance; less on train performance

- Car/train velocity; less on terminal dwell

- Fewer unit trains; more complex blocking

- Optimizing network, not just single divisions/terminals

- Longer full-tonnage trains; filling out tonnage enroute

- Running on schedules; more predictability

- Less firefighting; knowing what to expect

- More flat switching; less humping

- Driving decision making to the local level; less bureaucracy

“The bottom line is that we’re doing more with less,” Wolf said. “But whenever you have higher utilization of assets, you’re going to have accelerated degradation of those assets. We have to understand that we’re putting more stress on fewer components, and that wheel and rail wear, ballast conditions, and other aspects of track are all going to change — dramatically, sometimes.”

The operational changes associated with PSR affect track maintenance, and they have the potential to affect the derailment causation. “Underscore potential, Wolf said. “I’m not saying this is happening. But I’m here to sound the warning that those of you involved in the track structure, track maintenance, or derailment prevention should be aware of these factors.”

Wolf, who is the author of The Complete Guide to Modern Derailment Investigation, knows of what he speaks. He cited data (from an article by Bill Stephens in the November 2021 issue of Trains) indicating that all of the Class Is regularly operate trains up to 12,000 feet or more. Systemwide averages on the big six systems range from 6,900 feet at BNSF to 9,359 feet at Union Pacific. Since adopting PSR in 2018, UP’s train length has increased by 30%, with a goal of increasing its average train length to more than 10,000 feet.

With longer trains comes higher tonnage. Concurrent with that, train speeds have declined industry-wide from an average of 25 mph to 20 mph over the past two and a half years, Wolf said. “Lowering train speeds by 5 mph can have a significant effect on lateral curving forces. As speeds decline, we may find that we have excessive elevation in curves. The superelevation that was set based on timetable speeds and operating practices 10 or 20 years ago may be dramatically different from what is required by operating parameters today.”

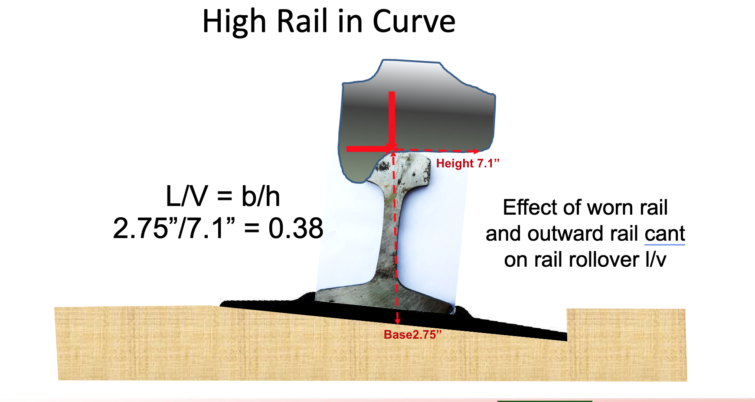

Improper rail cant, which can be caused by improper curve elevation due to changes in train speeds, can lead to differential plate cutting on timber ties. “This reduces the b/h ratio to initiate rail rollover, and ultimately will lead to greater risk of rail rollover, especially on the low rail side. Excessive plate cutting on the low side of the curve due to too much elevation can actually increase elevation and worsen the situation,” Wolf said.

Long, heavy trains can also generate dynamic slack effects that manifest themselves at the wheel/rail interface and are transferred into the track structure. “Braking longer, heavier trains on long downhill grades also generates more friction, which generates heat, which can increase rail temperatures,” he said. Brake pipe/trainline-related issues on longer trains can also cause sticking brakes, especially in cold weather, and wheel flats that generate high-impact loads into the rail and track structure.

Higher rail temperatures can impact the effectiveness gauge-face lubrication and top-of-rail friction modifier retention rates, and factor into the potential for track buckling. Higher rail heat, along with additional wheel forces, can further reduce the retentivity of greases and friction modifiers, causing less material to be carried down the track. Maintenance forces need to closely monitor rail friction levels to make sure that gauge-face lubricators and top-of-rail FM applicators are properly spaced and that the material output rates are appropriate for longer, heavier trains, Wolf said.

Longer trains also require more horsepower, which can override the ability of rail anchors to prevent the longitudinal rail movement associated with traction and braking forces, which tend to push rail downhill on grades. “Inspectors have to pay close attention on ruling grades to see if the rail is moving through the anchors, dragging ties, or otherwise overstressing the anchor system,” Wolf said.

Research and findings from derailment investigations have provided evidence that the increased longitudinal (and lateral) loading associated with increased levels of traction have been a primary factor in broken spikes. “Investigations on Norfolk Southern, for example, showed a correlation between broken spikes and the introduction of high-adhesion AC locomotives on the territories where the spike breakage occurred,” Wolf said.

Other areas to monitor for potential effects of PSR include changing wear patterns on rail, fasteners, ballast, crossties, and changes in track geometry, as increases in drawbar forces due to bigger trains will exert higher lateral and vertical forces on the track structure.

“The bottom line is that operating precision and reliability cannot coexist with maintenance interruptions, disruptions, slow orders, signal malfunctions, derailments, and human failure,” Wolf said. “To operate a reliable, precision/scheduled network we must be vigilant and eliminate disruptions and outages.”

###

Bob Tuzik is Publisher and Editor-in-Chief of Interface Journal (www.interfacejournal.com)

This article is based on a presentation made at Wheel/Rail Seminars’ 2022 Wheel/Rail Interaction conference.

The image above is from Wolf Railway Consulting, the 2022 Wheel/Rail Interface conference, and Interface Journal.